Engine performance is always a compromise. Design an engine that provides strong low end torque and high speed performance suffers. An engine designed for high speed power usually offers poor low speed performance. The design of several engine components will affect how an engine performs. These include compression ratio, the number of valves, intake manifold tuning, and exhaust system volume and length, but none of them affect engine performance as much as camshaft design.

A camshaft, sometimes called a "bump stick" because of the many egg-shaped lobes or bumps on it, has the job of opening the engine's valves at the right time. A camshaft doesn't look like anything very special but it is really the heart of the engine. Change the camshaft and the engine runs completely different. Before deciding on camshaft design, an engineer must know the intended use for the vehicle. Obviously, vehicles designed for towing require lots of low speed torque and sports cars can use high speed power better, although low speed torque can be useful too. Transmission ratios, final drive gearing, and vehicle weight are also factored in when picking a camshaft. Install the wrong camshaft and the vehicle is a dog; sluggish, hard on fuel, and a pain to drive. Get it right, and it is fun to drive.

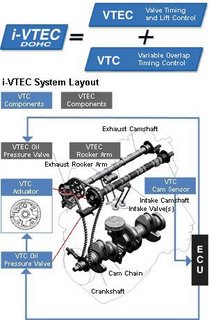

Although elusive, a camshaft that can provide reasonable low end torque and high speed performance is possible. Some manufacturers have used variable camshaft timing mechanisms to accomplish this. By advancing the camshaft position in relation to the crankshaft position, low speed performance is enhanced because the valves are closed sooner and cylinder pressures are higher at low rpm. Retarding the camshaft position lets the valves close later resulting in better engine efficiency at higher rpms. Variable camshaft timing is a partial solution. Honda has gone one step better.

Click here to find out more!

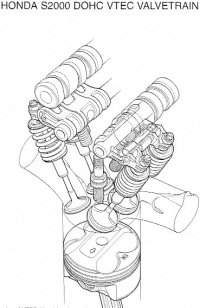

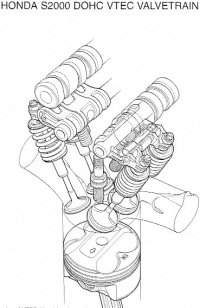

Honda's answer to good engine performance at all engine speeds is called VTEC. VTEC is an acronym for Variable Valve-Timing and Lift Electronic Control. By using the engine computer to vary both valve timing and valve lift, the engine's volumetric efficiency and performance are increased. Honda uses VTEC technology on a wide range of Honda and Acura passenger vehicles; from performance cars such as the S2000 sports car, to economy cars like the gas/electric hybrid Honda Insight.

VTEC design is like having two different camshafts in the engine. One camshaft for low rpm performance while the other provides high rpm performance. The VTEC difference is that both camshaft designs are on the same shaft!

At low engine speeds, the valves are opened by rocker arms or followers that ride on low rpm cam lobes. These cam lobes give a relatively short valve lift and duration (length of time the valve is open) to ensure good cylinder filling at low engine speeds.

As engine speed increases, the engine's computer operates a hydraulic spool valve that sends oil pressure to pins in the camshaft followers. The oil pressure moves the pins into a position that locks the followers for the low speed cam lobes onto an "extra" follower. Until now, the extra follower has not been operating any valves. It has just been following the contour of a separate high lift, long duration cam lobe. With the camshaft followers locked together, the low rpm followers are forced to operate at the same rate as the high rpm follower and the valves are lifted higher and longer.

It sounds complex, but its operation is smooth, reliable, and amazing. On Honda's S2000 high performance engine, the VTEC shift from the low rpm cam lobe to the high rpm cam lobe occurs at nearly 6000 rpm! On Honda's high performance sports cars, the transition from one cam lobe to the other is very noticeable, accompanied by a surge in acceleration and a sporty growl from the exhaust. On luxury models or the Honda Odyssey van, the transition is so smooth it is barely noticeable.

VTEC technology has been around for several years, and the design has proven reliable. Its benefits to the consumer are increased performance at all engine speeds, whether you desire better fuel economy and smoother idle at low rpms, or better acceleration at higher rpms.

Until the manufacturers come out with electrically-operated valves that replace traditional camshafts and offer the ultimate in valve timing design, Honda's VTEC technology is the best solution yet.

How VTEC work video :